Plastic Strapping for Packaging: A Comprehensive Guide on When and Why to Secure Your Goods

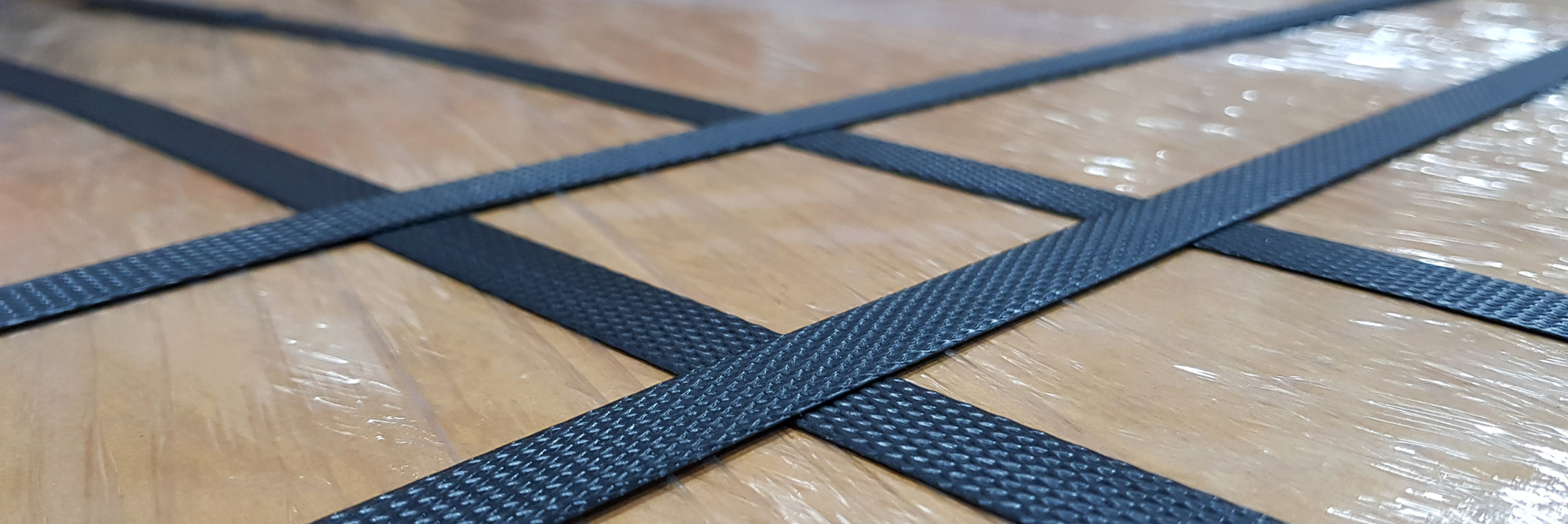

In the dynamic world of logistics and supply chain management, the importance of efficient and secure packaging cannot be overstated. Among the myriad packaging solutions available, plastic strapping has emerged as a versatile and reliable method for bundling and securing goods. This article delves into the various scenarios where plastic strapping is a preferred choice, shedding light on its benefits and the industries that can significantly benefit from its application.

1. Heavy and Bulky Items:

Plastic strapping is an excellent choice for packaging heavy and bulky items. Whether you are dealing with industrial machinery, construction materials, or large electronic components, plastic straps provide robust support, ensuring that the items remain securely bundled throughout the transportation process. The tensile strength of plastic strapping makes it well-suited for handling substantial loads.

2. Palletised Shipments:

Palletised shipments are common in the logistics and manufacturing sectors. Plastic strapping is particularly effective in securing palletised loads, preventing shifting or tumbling during transit. Its flexibility allows it to conform to the shape of the pallet and the goods, creating a stable and secure packaging solution. This is crucial for maintaining the integrity of the entire shipment and streamlining the loading and unloading processes.

3. Resistance to Weather Conditions:

Plastic strapping exhibits a high level of resistance to various weather conditions, making it an ideal choice for goods that may be exposed to the elements during transportation. Unlike some other strapping materials, plastic remains unaffected by moisture, preventing deterioration and ensuring the straps retain their strength even in adverse weather. This makes it particularly suitable for long-distance shipping or items transported in open-air environments.

4. Cost-Effective Solution:

In comparison to alternative strapping materials, plastic strapping is often more cost-effective. It provides a balance between strength and affordability, making it an attractive option for businesses looking to optimise their packaging costs without compromising on security. The ease of procurement and the recyclability of many plastic strapping materials also contribute to its cost-effectiveness.

5. Ease of Application:

Plastic strapping is user-friendly and easy to apply, making it a preferred choice for industries where efficiency in packaging is crucial. The use of strapping tools and machines streamlines the strapping process, reducing labour costs and ensuring consistent and secure strapping. This is particularly beneficial in high-volume operations where speed and accuracy are paramount.

6. Customisation and Branding:

Plastic strapping comes in a variety of colours and can be customised with branding or labelling. This not only allows for easy identification of packages but also serves as a branding opportunity for businesses. Companies can use coloured strapping to differentiate between product categories or to align with their corporate colours, enhancing brand visibility throughout the supply chain.

7. Recyclability and Sustainability:

As sustainability becomes a focal point in packaging considerations, plastic strapping stands out for its recyclability. Many plastic strapping materials are made from recyclable materials, contributing to environmentally friendly packaging practices. Additionally, the lightweight nature of plastic strapping can lead to reduced transportation costs and lower carbon footprints.

In conclusion, the use of plastic strapping for packaging goods is a versatile and practical solution for a wide range of industries. From securing heavy machinery to palletised shipments and withstanding diverse weather conditions, plastic strapping offers a combination of strength, cost-effectiveness, and ease of application. As businesses continue to seek efficient and sustainable packaging solutions, plastic strapping proves to be a reliable choice in enhancing the security and integrity of goods throughout the supply chain.