Choosing a Pallet Wrapper

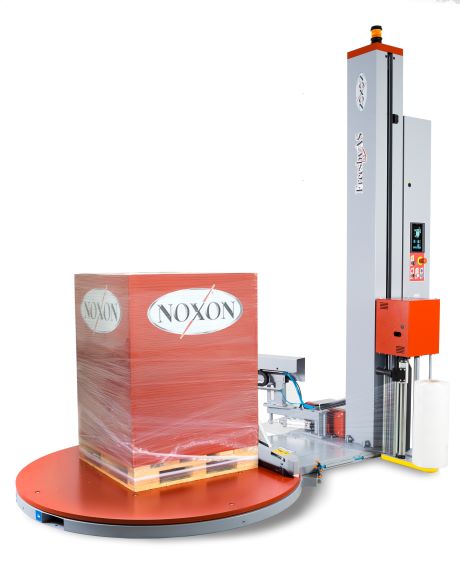

For those considering a pallet wrapping machine for the first time or looking to update and replace current machines there are many considerations. Some of those are considered in this short overview, following the launch of the European made NOXON Pallet Wrappers in the UK for Plus Packaging.

- Machine Reliability and Compliance

- Type of Stretch

- Service Provider

- Purchase Type

- Other Considerations

Reliability and Compliance

Pallet wrapping machines are designed and manufactured all over the world, then distributed through packaging companies all-round the UK. Here’s a quick overview of the differences between the country of origin where they are made.

China

Many machines originate from China. As you can imagine, these are well priced, but reliability and compliance can be challenging. Its also worth considering the length of time that parts could take to arrive and whether there is a valid warranty on the machine. Also see below options on the type of machine available – is it right for your application? In some cases Chinese machines are good for an entry level machine.

Taiwan

These machines are a quality upgrade from China – largely more reliable. Good UK distributers will hold parts and be able to provide service, but when this goes wrong, it can mean long delays. Check machine specifications carefully as machines made in Taiwan are often made to a distributers ‘recipe’ and short cuts may have been taken on design and quality. Machines are generally reasonably priced but limited ranges are available.

Europe

Machines that are made across Europe are another step up in quality and often the range is much larger. Importantly, machines are far more likely to be compliant with EU and UK regulations, a key point for passing health and safety audits. Service providers will have strong back up as parts are quickly available and warranties almost always in place. The pricing can be a challenge on more complex machines, but some manufacturers are developing entry level machines that can compete with imported options.

Type of Stretch

There are three key types of stretch to consider – all to do with getting the most out of your pallet wrap and cutting the cost to wrap each pallet. This can come down to how many pallets you wrap each day. Mechanical or Core Break Machine

These machines don’t apply stretch to the wrap before it is applied to the pallet. As the machinery required to stretch wrap adds cost, the advantage of a core break machine is a very attractive price and is ideal for those switching across from wrapping pallets by hand.

Power Pre-Stretch Machine

PPS machines apply a set stretch to wrap, often around 250%. In simple terms this means that the machine stretches 1m of wrap 2.5 times – so you end up with 3.5m for every 1m of film on the reel. This reduces the cost per pallet wrapped dramatically. It's key to take into account the amount of and type of pallets you are wrapping when deciding which machine to go with. If it’s over twenty pallets a day you should be carefully considering a Power Pre-Stretch machine as your long-term costs will be significantly reduced.

Dual Motor Machine

Two motors over the rollers in the film carriage allow you to select the exact stretch that you need. For light weight pallets you may wish to stretch the wrap much less so as not to push the contents around. A dual motor machine allows you to control this, thereby saving further costs as you wrap each pallet to the right specification.

Service Provider

The service provider is a key consideration for your purchase. A pallet wrapper breakdown can lead to long down-time in your production and if you aren't covered – high service expenses. Make sure you have at least one year warranty on your machine and that your provider can provide service repairs within stated and accepted times.

It’s also important to check extras, service costs, installation and training at point of purchase. Good distributors will ensure you are aware of any extras you require, how much installation may cost and what training, if any, your team will receive.

Purchase Type

There are several ways to purchase a pallet wrapper. Largely, its cheapest to simply buy the machine outright, perhaps with a service contract on it. But there are often other methods available.

Rental

Some distributers will have rental fleets of machines. This can be very useful for a co-pack job or a one off where you only need the machine for a short time.

Hire Purchase

Easier on cash flow – often run over two years, the cost of the machine is spread over a rental and you end up owning the machine. Can add to the cost of the machine.

Bulk Order

Useful for overcoming difficult Cap-Ex procedures, some companies will allow a large consumable order, for the Pallet Stretch Film itself, which covers the machine too. The film is called off over a period of time, often one year.

Other Considerations

Here’s a helpful list of other considerations before you purchase a pallet wrapper…

- Standard turntables are 1650mm – will that cover your application or do you need a special make.

- Standard mast heights are 2200mm – again, ensure that this will cover all of your pallet heights.

- Weight capacity ranges from 1500Kg up to around 3000Kg – check your pallet weights and ensure the machine will be suitable.

- Entry Level and High Grade machine ranges are available – ask your distributer to specify for your application

- Make sure the machine will fit in your warehouse or space allocated!

We hope this has given you a good summary of all the different aspects to think about when choosing your machine supplier. You can explore our range of Noxon machines here.

If you'd like any further information or for a member of our team to visit, please give us a call 0151 486 4800.

.png?width=1200&height=600&ext=.png)